Ask Latest Price

Video Channel

Brand Name :ZG

Model Number :MS

Certification :CE

Place of Origin :CHINA

MOQ :1 piece

Price :USD10/piece

Payment Terms :L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability :10000 pieces per month

Delivery Time :3 working days

Packaging Details :Strong wooden box for Global shipping

Refractoriness (℃) :1770< Refractoriness< 2700

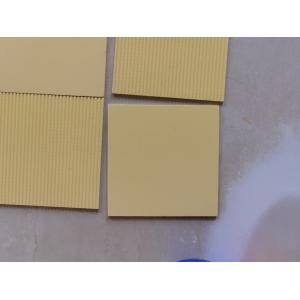

Material :Zirconia, ZrO2

Application :Sintering kiln

Shape :plate, tray, gasket, tile

Specification :Customized by Customer

Color :Yellow, white

more